THE JETPATCHER PROCESS

The Jetpatcher is suitable for road maintenance works including potholes, edge deterioration, cracking etc., and regulating low areas of paved roads.

The operation is carried out by first removing all dust, debris and moisture from the affected area. Then sealing the defect using cold-applied bitumen emulsion and filling the defect to the required level using an aggregate/cold bitumen emulsion mix, all from the single delivery hose. The Jetpatcher is manually operated from the self-contained vehicle. It carries all equipment and materials required to undertake the operation, including signage to comply with carrying out mobile works in rural and urban environments.

The 4 Stage Jetpatcher Process

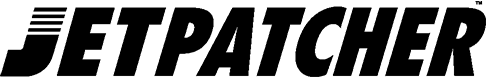

Clean

Using the high volume blower, the Jetpatcher easily blows all loose debris and even water from the pothole; cleaning it, and preparing the hole for an effective patch.

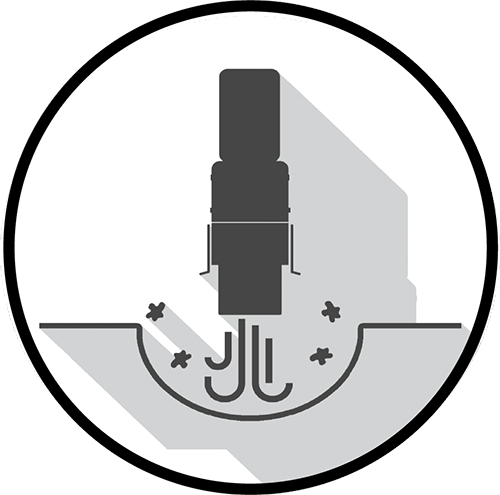

Prepare

The Jetpatcher now coats the pothole with an asphalt emulsion which seals the pothole and prevents further damage from occurring, due to moisture.

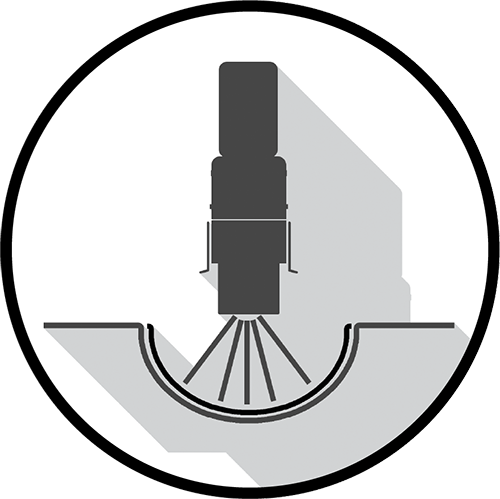

Fill

As the aggregate passes through the nozzle it is coated with emulsion and sprayed into the hole or broken road edge. The Jetpatcher asphalt mix is sprayed at speeds of up to 100kph, compaction from the bottom up is achieved giving a result which is denser than rolled asphalt.

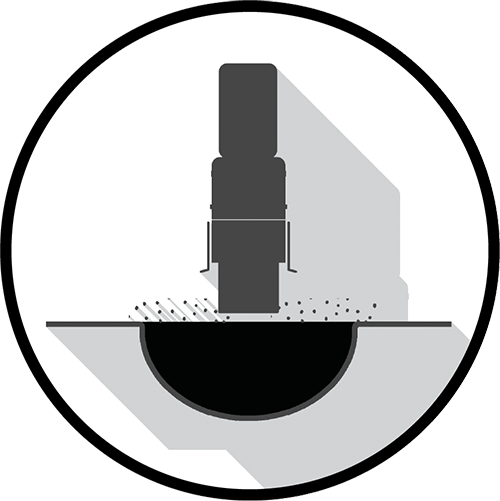

Seal

The wet top of the repaired area can now be protected from traffic flow using either dry aggregate, sprayed from the Jetpatcher, or, for inner city work (where loose chip is a potential hazard), sand from the optional sand hopper, which can be built into the Jetpatcher unit on request.